"The Best Gallon of Water":

Men and Work at the McNeill Street Pumping Station

Pumphouse built in 1921

History

The McNeill Street Pumping Station is located on Cross Bayou near downtown Shreveport, Louisiana. In operation from 1887 until 1994, it was the first water plant facility established in Shreveport and only the second in the state. At a time when fewer than 10% of the water plants in the nation filtered water before releasing it, McNeill Street Pumping Station instituted sand filtering in 1890. In 1904 as the demand for water grew, McNeill was among the first plants to use reinforced concrete for filter tanks. McNeill was also on the forefront of the technology of using chlorine to disinfect the water supply when it began using a powdered form of chlorine in 1911 and liquid chlorine in 1914. In fact, one of the first 12 liquid chlorinating machines made in the nation was installed at McNeill in that year.

The original steam-driven pumps, magnificent examples of industrial age technology, are still in place, though they were retired in 1980. These surviving examples of steam-powered machinery are exceedingly rare, especially in original context, and those at the Pumping Station are amazingly still operable due in large part to the attention of personnel from the Shreveport municipal water system. While touring the facility in 1980, Robert Vogel, former Curator of Heavy Machinery and Civil Engineering at the Smithsonian Institution National Museum of History and Technology, noted that two of McNeill’s Worthington pumps may be the only surviving examples of that type of pump (http://www.mcneillstreet.org/OldHiSrv.htm). Largely through the efforts of retired city councilman and former mayor, John Hussey, the McNeill Street Pumping Station was placed on the register of National Historic Sites and was designated a National Historic Landmark.

John Hussey: In 1978, when I became a member of the [city] council, the McNeill Street Pumping Station was actually used as part of our water supply and the power was steam power and that’s what made it unique. I got to know some of the fellows in the water department and they told me that I should come see this pumping station. Of course when I went there, I had no idea what I was seeing, but then as they started to talk about it, it became obvious to me how unique it was.

The Pumping Station was also designated as a Historic American Water Landmark by the American Waterworks Association, and in 1999, the American Society of Civil Engineers designated it a National Historic Civil Engineering Landmark.

Plate from Worthington Pump

In 1999, the McNeill Street Pumping Station Preservation Society was formed to promote and help preserve and restore the plant. The long term objective of the Society is to create a technological and cultural museum at the site. Through the efforts of the Society and its Board of Directors, a number of grants have been secured to help preserve the facility, prepare it to receive tours, and to collect oral histories from former employees. Information regarding the Pumping Station and the Preservation Society can be found online at http://www.mcneillstreet.org/default.htm. Working with the Preservation Society and former employees, the Louisiana Regional Folklife Program, Region 2, documented the occupational folklore associated with the Pumping Station. Occupational folklore is made up of those traditions that are associated with the working life of people. There is a “sense of place” connection to the workplace, its history, specialized language, teaching methodologies, and other traditions that differ from traditions associated with family, religion, region, or ethnicity. The bonds forged among the work force in a particular occupation are built upon common experience and hard work. The former employees of the Shreveport Water Works and the McNeill Street Pumping Station share such a common bond.

Charles Foster: When I came to work in 1939, McNeill was just another unit in the Water System. The most important part of it was [the] Cross Lake Pump Station. Thomas L. Amis was the first superintendent and operator of the whole system, and I went to work under him. And I lived with it, grew up with it, from 1939 on, and the last fifteen years, I was in charge of the whole thing myself.

Felix Horton, Donald Spurgeon, Billy Ivory

One of the greatest resources available to the McNeill Street Preservation Society’s efforts to document the workings of the Pumping Station has been former maintenance supervisor Billy Ivory.

Charles Foster: Billy Ivory knows more about McNeill station than anybody, the operation of it and everything, than any man alive.

Friends and former co-workers Billy Ivory, Felix Horton, and Donald Spurgeon got together recently at the Pumping Station to reminisce about their work experiences and the camaraderie they shared. The great regard they have for one another was apparent, as was their love for this wonderful facility.

Billy Ivory: I started work here in 1957. When I first started working here, I was cutting grass. I cut grass, I guess, for at least ten years and then I moved up into maintenance. This place grows on you. When I first came to work here I was making ninety-nine cents an hour, and every week I was gonna quit, I was just gonna quit. But I stayed here thirty-four years.

Donald Spurgeon: I transferred from the sanitation department. I started here as a fireman [took care of the boilers] and worked up to operator [monitored operating pressures, kept activity log]. Then I went to work with Billy in maintenance. I operated for about ten years and then I worked for Billy for about three years.

Felix Horton: I started work at the Spillway. In 1972, the Spillway was paying $400 a month. A fireman at McNeill was getting about $625 or something like that, so I transferred over to here. This job was the only job that I ever had that I enjoyed coming to work. My wife used to say, “Why you leave so early to get to work?” I’d come to work an hour before work time, because I loved these folks, I loved the work here.

Guiding the visitors through the Pumping Station, the three men documented each step in the process of taking water up from Cross Bayou, treating it, filtering it, and sending it out to the city.

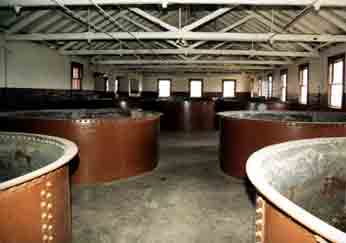

Rapid Sand Filters

Billy Ivory: In the beginning, when we first built this plant...they just picked the water up out of the bayou down there, pumped it up to the basin, put some Purex in it and let it set for a couple of days, and then they’d pump it out to the city. But they never filtered it or nothing. Then they started rapid sand filtering it. And we have the seven filters here - this plant had the first filters to ever filter water in the United States.

Chemicals were added to the water to remove impurities and improve the taste. Pressure on the boilers was monitored constantly, and the men worked under a series of checks and balances to ensure that clean water was available to meet the needs of a growing city.

Billy Ivory looks into

the mixing chamber, where

the chemicals were added

into the water

Billy Ivory: The alum was used as a coagulant, it would act like a magnet and reach out and collect the turbidity in the water and it would sink down to the bottom. It kind of softened the water. The chlorine was used as disinfectant. The only time we used carbon was when we had taste and odor and it helped reduce the taste and odor in the water.

Lee Holyfield was the plant manager. He could walk in the shop and tell you if the air under the boilers was right. And before he would leave in the evening, he would put a penny under one of those valves. And he would come back in the morning, the first thing that he’d do, he’d walk behind that boiler and he’ll open that valve and see if the penny would fall in his hand. That meant that valve hadn’t been opened. If that valve would’ve been opened, that penny would have been on the ground, but it was in his hand. I was just lucky enough to see that happen one day. Somebody had a session with the boss that day!

Mr. Hirsch was the chemist. They had a board up there. He would just go to that board and put on it what he wanted [the chemical distribution] set on. And he might come out there fifteen minutes and go back behind those machines and if that scale wasn’t set on what he said it was, then he’ll let you know about it.That was one of the things that, I guess, fascinated me about it. They wasn’t making no money, but they all loved the job and they wanted to send the best gallon of water away from here they could. And they worked at it. They made sure that the water that was left here was right.

Donald Spurgeon with steam driven pumps

Water production required constant activity, so shifts were manned around the clock.

Felix Horton: You were on call twenty-four hours a day, seven days a week. If it come a big snow you stayed here if it was two days, five shifts or six shifts. You stayed and worked until...your relief was able to get to work. If it was snowed under and they couldn’t get here, you had to stay here.

Donald Spurgeon: When these pumps were down, we stayed here and worked on it until it was pumping.

Felix Horton: You didn’t have a lunch hour. You ate when you got a chance. You worked straight through, in other words. And we had a kitchen. We could prepare our food, but we didn’t have a lunch break you know. If we had a few minutes we didn’t have nothing to do, then we sat down and ate right fast. Maybe one of us was eating, and the other was watching the boilers and the pressures. The boilers and pressure was the main thing for the operators, because if you let the pressure get up, you’d blow out a line out here.

Felix Horton: We had a lot pride in our work. Everybody worked together, you know.

Donald Spurgeon: We had this place spit-polished and shined all the time.

Billy Ivory: The boilers used to be graphite. We’d put oil and graphite on them - it was just beautiful. The plaques on the boilers are all brass. You had your red handles on everything - it made it look good. Every Friday we polished brass - every piece of brass. And everybody polished brass. They didn’t care what your status was, you polished brass. And it was polished - it wasn’t polished at - it was polished. They made sure that brass was polished.

New employees were taught on the job. There were no manuals, no classes, and no formal training period. As a rite of passage, new workers were often the subject of jokes and pranks. Even among men who had worked side by side for years, friendly banter and competition was common.

One of three

water tube boilers

within the

pumping station

Billy Ivory: You learned from someone else, because there was no literature to tell what this was and what that was. So mostly the older guys just passed on to you what someone else taught them to do. That’s the way we took care of it.

Felix Horton: First day I came, transferred over here, I was being trained as a fireman, and the guy training me told me all about the boilers, about the pressure, and about blowing the boilers down from top to bottom. And he said, “Now, watch that pressure. When that water level gets back up to where it’s supposed to be, cut this valve off here.” So I watched the thing and it got up right where it was supposed to be and I went to cutting it off, and I turned and I turned, but it wouldn’t cut off. Finally I went to him and I said, "Hey, I can’t cut that valve off." And then he just about died laughing. It was a prank he pulled on me - kind of an initiation thing that they’d do to you. We had one operator here. Every time he’d go on vacation, he’d come back and we’d say you had to retrain him again.

Donald Spurgeon: It was me!

Felix Horton: That was Donnie. We’d pick at him and say we had to retrain every time he went on vacation. But he was good-natured and he took it good - he knew we were picking at him.

Billy Ivory: The only good operator was operating, and when he’d leave he wasn’t no good to the operator who came on after him. Because one operator would come on and he’d say, "Well, he could’ve did this, he could’ve did that.” So the only good operator was actually operating at that time. But, it was always something. It was always laughing in this place.

Felix Horton: The boss at that time, he could chew you out and get mad. And in a minute he was out there doing something for you, helping you to do something. He was that type of fellow.

Billy Ivory: He would give you the shirt off his back and ten minutes later he’d take that same shirt and make a rope and hang you! It’s just the way he was. He was something else. But, everyone pitched in. If I needed an operator to go in the basin and help wash the basin, then the operator would say, “Well, I’ll take care of it.” It wasn’t, “It’s not in my job description.” They’d just fall in and go ahead and help you, that’s the way it was. It was tight.

Throughout the day spent walking through the Pumping Station, each man recalled with fondness his time spent working there.

Felix Horton explains

how to start the pumps

Billy Ivory: I have great memories of the friends we met here and the times we had, the relationships we had with each other. When I first came here, all these guys were around here and they were working, wasn’t making any money, but yet they were still enthusiastic with the place. It just grows on you. I can spend time out here and go home that evening, I’m tired and everything, but I’m just totally relaxed, because I’ve been at McNeill. I enjoy being out here, I enjoy what I’m doing out here. So what it means to me, I don’t know, but I can’t stay away from out here.

Felix Horton: People that worked over there at the other plant, you couldn’t get them to come over here and work because it was too hot and too hard. The work was hard, but I loved every minute that I worked here. After I got the morning shift, I’d get up at four o’clock every morning and I didn’t go to work until six. And I’d leave home about 4:45 and get here about 5:15 and visit with whoever was working night shift until it was time to go to work. And you could have a problem, everybody that worked here would help you. If you was sick, they’d call and see about you. And I don’t know, there’s just something about McNeill that grows on you and you just want to come back. It’s the first time I’ve been back since I retired in 1988, January, and I got to trying to think how the pumps operate, how you turn them on, and I wondered if I can still remember all of that. But as soon as I saw that pump, I knew how to work it, because it’s just something that you get gratification out of, seeing those pumps run. It’s just like when you build something with your hands, and use your hands, you’re taking pride in what you’re doing. And I took pride, I really loved this job. And the times is changed, they done away with the steam engines, but in my heart they’re still here.

One of two colossal flywheels

within the pumping station

Donald Spurgeon: I feel like Billy and Mr. Horton does. It’s just something that pulls you out here. And it’s nothing like seeing both of those big flywheels spinning at the same speed, that’s something to sit and watch. You get them engines running the same speed and holding ninety pounds, you’ve got it going. I’ve been back out here a few times since I left. I wish I hadn’t left, and I come back in here and see this and I hope that they do something with it - clean it up, remodel it, and restore it, because I don’t believe there is any place in the United States like this place here. And we got it here and we need to take care of it and keep it. I’d go back to work out here if they’d let me.

Felix Horton: Yeah, I would too.

Billy Ivory: My baby daughter, she loved this place, too. When she graduated from high school, she said, “Daddy, I want to go take pictures in my gown at McNeill.” And we came out here and we taken pictures of her right there. I don’t know whether this place had anything to do with it, but now she’s an electrical engineer. That’s what she wanted to do, she loved this place.

This place has some effect on you, you don’t know what it is, but you will always be here.